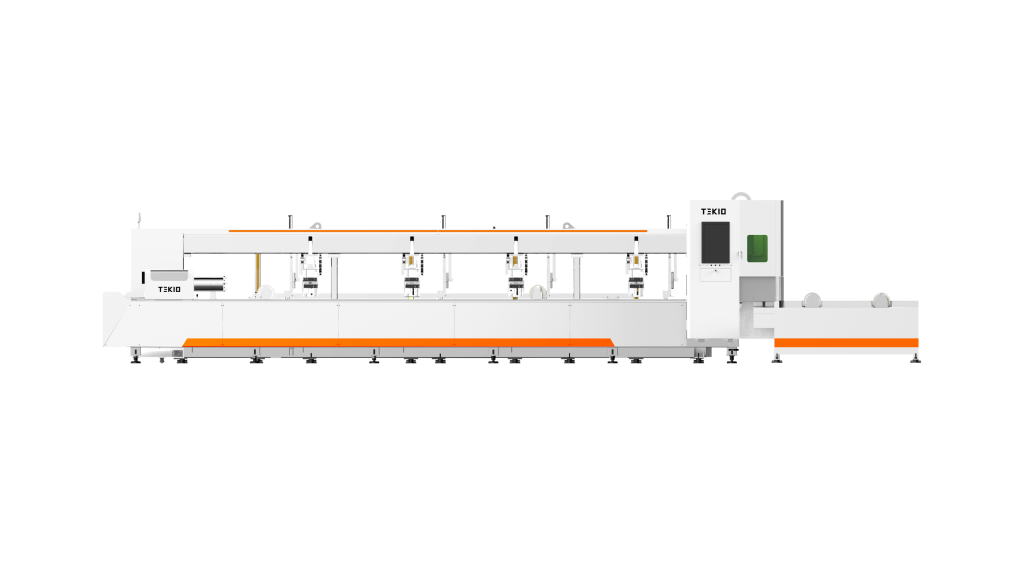

Automatic Auxiliary System

Automatic loading and unloading system is used to improve the utilization of machine tools and work efficiency, significantly saving labor cost and resources and catering to various needs of simple material handling to full automatic operations.

◆ Automatic loading and unloading system consists of an lifter (include vacuum chuck and fork), exchange tables (include raw material and leftover material tables) and a transmission mechanism

◆ Fast processing of materials, save installation time.

◆ Save labor cost, improve machine utilization rate.

◆ Unattended operation is initially realized in workpiece production and processing

◆Customized specifications per order

Working Procedure:

Loading: the raw material platform transports the raw material to the exchange area,

and the vacuum suction lifter sucks up the raw material (underneath protected by fork) and move to the working table where the material put down.

Unloading: raw materials and leftover materials are exchanged at exchange table of the laser cutting machine first.

Then the lifter moves down when the forkreach out to the scrap underneath to pick up the leftover material and move to the exchange area. Finally, the leftover material is put on platform for the scrap.

Controlled by the preset program, auto loading and unloading system automatically complete the whole process from loading, cutting to unloading.

|

Model |

|

|

Plate size |

3000x1500m (customized size) |

|

Stack thickness(load) |

0.8-20mm |

|

Stack thickness(unload) |

0.8-20mm |

|

Maximum plate weight |

500kg |

|

Stack Layers |

7 |

|

Overall dimension |

12000x9000mm(take plate size 1500x3000mm as an example) |