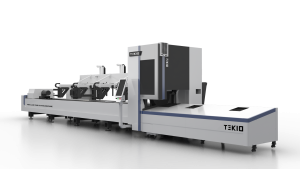

Is it profitable to purchase the use of laser cutting?

As a practitioner in the metalworking industry, purchasing the use of laser cutting can offer a variety of advantages and bring profit to your business. Here are some of the benefits of laser cutting for metal fabrication

High precision and accuracy.:Laser cutting offers a high level of precision and accuracy, which is critical for metalworking applications that require complex cuts or intricate designs. Laser cutting technology can achieve very high levels of precision and repeatability, ensuring consistent and high-quality results.

Versatility:Laser cutting can be used to cut a wide range of metal materials, including steel, aluminum, copper, brass and titanium. It can also be used to cut sheet metal and sheet metal of varying thicknesses, making it a versatile solution for many metalworking applications.

Speed and efficiency:Laser cutting is a fast and efficient process, especially when compared to traditional cutting methods. The use of computer-aided design (CAD) software and automated laser cutting machines can significantly reduce the time it takes to cut and shape metal materials.

Reduced waste: Laser cutting minimizes waste by optimizing the use of materials and reducing the need for secondary processing. This results in cost savings and increased environmental sustainability.

Customization: Laser cutting technology can create intricate designs that allow for greater customization and creativity in metalworking applications. This is particularly beneficial for companies that specialize in creating unique or custom metal products.

In terms of profitability, investing in laser cutting can save money in the long run because it reduces waste, increases efficiency and improves productivity. However, the initial investment in laser cutting equipment is relatively high, so it is important to perform a cost-benefit analysis to determine if it makes financial sense for your business. In addition, for companies with smaller workloads or limited budgets, if the main material processed is a high percentage of thin sheets, you can purchase multiple low-power laser cutting machines to increase productivity.