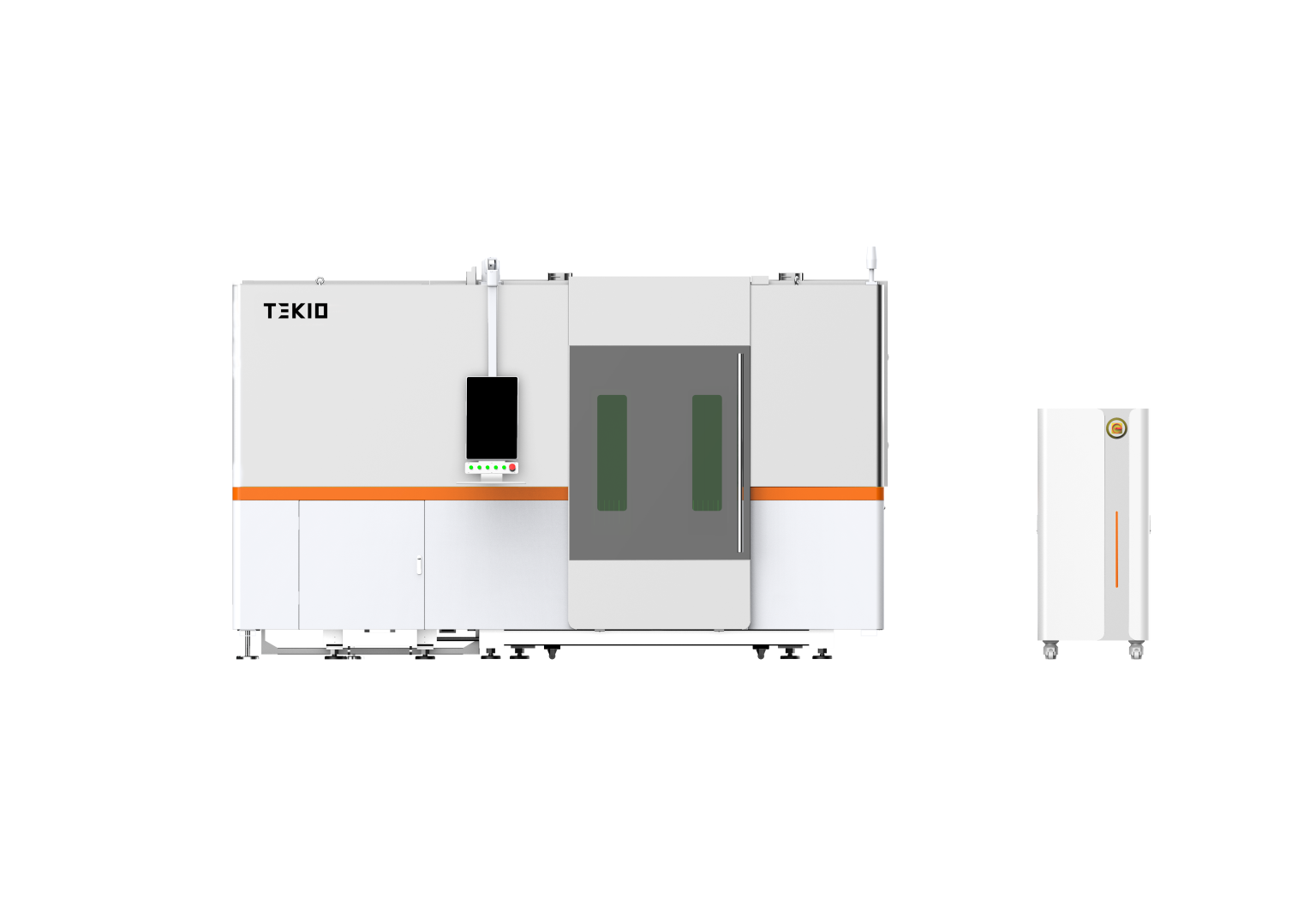

Dvojí použití

Uzavřený typ desky a trubky Integrovaný řezací stroj může udržovat dílnu v čistotě tím, že účinně zabraňuje šíření prachu během operace řezání. Konstrukce jednostranného otvoru je vhodná pro nakládání a sledování stavu řezání.

Parameter&configration List

| Item | Subitem | Tekio 3015 Dual Function |

| Basic parameter | Working area | 3000mm*1500mm |

| Table load bearing | 810Kg | |

| Machine weight | 4T | |

| Fastest exchange time of platforms | 10S | |

| Machine overall dimensions | 9250*3950*2260mm | |

| Machine weight | 7800KG | |

| Operation parameter | Max. linkage speed | 150m/min |

| Max. acceleration | 1.2G | |

| Positioning accuracy | 0.03mm | |

| Repositioning accuracy | 0.02mm | |

| Optical system | Laser source | Ultron laser source |

| laser head | Tekio laser head | |

| Automatic focusing function of laser head | ● | |

| Multi-stage perforation Technology | ● | |

| smooth cutting technology | ● | |

| Mechanical system | machine bed | Welded by 8mm Steel Sheet/ Electric CNC Annealing/One-time Milling High Strength Rail Base with thick bearing wall of Rack&Rail |

| Servo motor and driver | VEICHI (X:1.1KW Y:1.7KW Z:0.4KW) | |

| Slideway | Italy PEK | |

| Rack | (T-win) | |

| Automatic lubrication function | ● | |

| Intelligent control system | Control system | CypCut 3000 |

| Display size | 24inches | |

| WIFI wireless control | ● | |

| Nozzle automatic calibration function | ● | |

| Process monitoring | ● | |

| Active obstacle avoidance function | ● | |

| Laser cutting technology database | ● | |

| Cutting gas automatic pressure regulation function | O2 | |

| Breaker | France Schneider | |

| Relay | France Schneider | |

| Electrical proportional valve | ●ED05(≤6KW) | |

| Plate cutting part system identification file format | GERBER文件、DXF、AI、PLT、LXD、NC | |

| Part of pipe cutting system identification file format | IGS IGS | |

| Tube processing parameter | Tube size range | T160:Round tube:Φ10-Φ160mm Square tube:□10-□160mm Rectangular tube:long side≤160mm T220:Round tube:Φ10-Φ220mm Square tube:□10-□220m Rectangular tube:long side≤220mm |

| Max. length of tube | tube maximum length 3m and 6m | |

| Cutting function of angle steel and channel steel | Optional | |

| Chuck drive types | pneumatic optional | |

| Chuck maximum load | T160: 140Kg 23Kg/m T240:280Kg 44Kg/m | |

| Maximum blanking length | 2m | |

| W axis rotation angle | Unlimited n*360 | |

| Max. rotational speed of W axis | 80RPM | |

| F-T3U axis positioning accuracy | 0.03mm | |

| F-T3U axis repositioning accuracy | 0.02mm | |

| F-T6U axis positioning accuracy | 0.05mm | |

| F-T6U axis repositioning accuracy | 0.03mm | |

| U axis maximum moving speed | 30m/min | |

| Laser abnormal alarm | ● | |

| Cutting abnormal alarm | ● | |

| O2 Gas low pressure alarm | ● | |

| Water cooler abnormal alarm | ● | |

| Laser protective glasses | ● | |

| Peripheral system | Water cooler | S&A/HanLi |

| Dust removal | Optional Centrifugal fan | |

| Note: | Cross-sectional shape error and bending degree must meet the requirements of GB/T 6728-2008 |