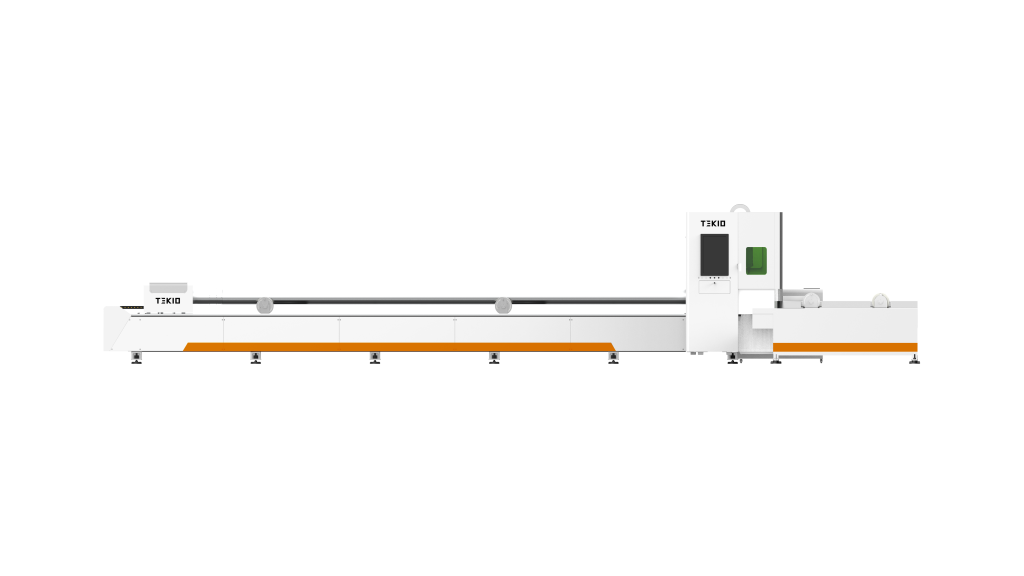

Faserlaser-Rohrschneidemaschine T240

Ausgestattet mit einem speziellen Schneidesystem, einfach zu bedienen, hohe Präzision, Professionalität, geeignet für das Schneiden von Spezialprofilen, während das optionale Palettensystem die Schneidekosten senkt. Weit verbreitet in Sportgeräten, Erdölpipelines, chemischen Anlagen und anderen Industrien. Es kann Kohlenstoffstahl und Edelstahl schneiden.

Parameter&configration List

| Item | Subitem | Tekio T240 | Tekio T360 |

| Basic parameter | tube cross-sectional shape | Round pipe, square pipe, rectangular pipe, oval pipe, long round pipe (runway round),and other pipes (Please ask product manager for other cross-section shapes) | Round pipe, square pipe, rectangular pipe, oval pipe, long round pipe (runway round),and other pipes (Please ask product manager for other cross-section shapes) |

| tube size range | Round tube Φ20-Φ240mm Square tube □20 - □240mm Rectangular tube:≤240mm Circumscribed circle diameter≤240mm | Round tube Φ20-Φ360mm Square tube □20 - □360mm Rectangular tube:≤3600mm Circumscribed circle diameter≤360mm | |

| Maximum machinable tube length | 6500mm/9200mm | 6500mm/9200mm | |

| Maximum tube weight | 200Kg 30Kg/m | 500Kg 83Kg/m | |

| Maximum blanking length | standard 2 meters | standard 2 meters | |

| Machine weight | 4500Kg/5800Kg | 4500Kg/5800Kg | |

| Dimensions | 11800×1800×2650mm/14800×1800×2650mm | 11800×1800×2650mm/14800×1800×2650mm | |

| Max. Chuck rotating speed | 130r/min | 80r/min | |

| X axis maximum speed | 150m/min | 150m/min | |

| Y axis maximum speed | 120m/min | 120m/min | |

| X maximum acceleration | 1.5G | 1.5G | |

| Y maximum acceleration | 1.5G | 1.5G | |

| Z axis maximum speed | ≥60m/min | ≥60m/min | |

| Processing precision(□38mm stainless steel square tube) | Φ20mm roundness | ≤0.10mm | ≤0.10mm |

| □20mm square diagonal size difference | ≤0.10mm | ≤0.10mm | |

| □20mm square position size difference | ≤0.15mm | ≤0.15mm | |

| Optical system | Laser source | Ultron laser source | Ultron laser source |

| laser head | TEKIO Laser Head | TEKIO Laser Head | |

| Automatic focusing function of laser head | ● | ● | |

| Multi-stage perforation Technology | ● | ● | |

| smooth cutting technology | ● | ● | |

| mechanical system | Chuck | Fully automatic self centering four jaw chuck- Pneumatic | Fully automatic self centering four jaw chuck- Pneumatic |

| Machine Body | Welded by 8mm Steel Sheet/ Electric CNC Annealing/One-time Milling High Strength Rail Base with thick bearing wall of Rack&Rail | Welded by 8mm Steel Sheet/ Electric CNC Annealing/One-time Milling High Strength Rail Base with thick bearing wall of Rack&Rail | |

| Chuck Qty | 2 chunks (3 chunks optional) | 2 chunks (3 chunks optional) | |

| X-axis、Y-axis、Z-axis、A-axis Servo motor and driver | VEICHI (Front Chucks:3.9Kw Rear Chuck:1.7Kw feed:2.4Kw X-axis:1.1KW Z-axis:400W) | VEICHI (Front Chucks:3.9Kw Rear Chuck:1.7Kw feed:2.4Kw X-axis:1.1KW Z-axis:400W) | |

| Jaw position control | ● | ● | |

| Standard blanking rack | ● | ● | |

| Slideway | PEK | PEK | |

| Rack | T-Win | T-Win | |

| Reducer | EREFAT | EREFAT | |

| Intelligent control system | Control system | cypcut 3000 | cypcut 3000 |

| Cutting Angle Steel and Channel Steel | Optional | Optional | |

| Automatic tube inspection | ● | ● | |

| Display size | 24inches | 24inches | |

| Automatic tube inspection | capacitance, equipment with loading system | capacitance, equipment with loading system | |

| Laser cutting technology database | ● | ● | |

| Auxiliary gas low and high pressure alarm function | ● | ● | |

| Cutting gas automatic pressure regulation function | O2 | O2 | |

| Breaker | France Schneider | France Schneider | |

| Relay | France Schneider | France Schneider | |

| Electrical proportional valve | ●AVENTICS ED05(≤6KW) | ●AVENTICS ED05(≤6KW) | |

| Oxygen Control Valve | AVENTICS | AVENTICS | |

| System identification file format | IGS | IGS | |

| Safety | Rear chuck and roller anti-collision | ● | ● |

| Laser abnormal alarm | ● | ● | |

| Cutting abnormal alarm | ● | ● | |

| Water cooler abnormal alarm | ● | ● | |

| Intelligent Flow Lamp Warning Function | ● | ● | |

| Peripheral system | Water cooler | HanLi/S&A | HanLi/S&A |

| Dust removal | Optional Centrifugal fan | Optional Centrifugal fan |