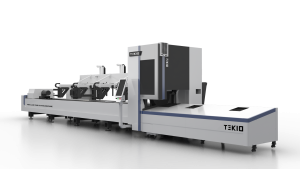

Laser Cutting Machines for Metalworking: A Comprehensive Guide

Laser cutting machines have revolutionized metalworking, offering unparalleled precision and speed in cutting a wide range of metals. From carbon steel to aluminum, copper and titanium, laser cutters have become an essential tool for the metalworking industry.

How does laser cutting work?

Laser cutting machines use a focused laser beam to cut metal. The laser beam is generated by a high-powered laser source and focused through a lens to produce a small, intense spot of light. This beam evaporates or melts the metal, creating a narrow kerf that separates the cut portion from the rest of the sheet or plate of metal.

What are the advantages of laser cutting for metal processing?

Laser cutting machines offer a variety of advantages for metal fabrication, including

High precision: Laser cutting machines can achieve very precise cuts with tolerances as small as 0.1mm, and a CNC program ensures consistent and accurate cuts every time.

Versatility: Laser cutting machines can cut a wide range of metals, including carbon steel, stainless steel, aluminum, copper and titanium. There are specialized laser tube cutters and laser plate cutters for metal pipe and plate parts. In addition dual-purpose plate and tube integrated machine can do one machine to handle pipe fittings and plate parts

.

Speed: Laser cutting machines can cut metal quickly, making them ideal for high volume production in the metalworking industry.

Minimal material waste: Laser cutters have narrow kerfs, which means they produce less material waste than traditional cutting methods.

Clean kerf: Laser cutters produce clean kerfs with no burrs, reducing the need for secondary finishing operations.

What are the different types of laser cutting machines?

Laser cutting machines are divided into three main types.

1.Fiber laser cutting machine

Advantages:

Fiber laser cutting machine uses fiber laser transmission through optical fiber, which can easily achieve flexible processing, and in the photoelectric conversion rate is higher, can reach more than 25%, the consumption of electricity is less. When cutting thin plates of less than 12 mm, it is the fastest and best cutting quality of all cutting machines in the market today. Using fiber optic transmission, the beam diameter is small, the cut gap is small, the spot quality is good, and can be used for fine cutting process.

Disadvantages:

The general price of fiber laser cutting machine will be more expensive. In addition in cutting thicker materials and cutting highly reflective materials in the cutting speed is very slow.

Market positioning:

The thin plate cutting below 12 mm has an absolute advantage, especially in the thin plate of high precision processing fiber laser cutting machine advantages are more obvious. Therefore, the market positioning of fiber laser cutting machine in, thin plate cutting precision processing and high efficiency required by manufacturers. At present, with the technological breakthroughs in high-power fiber laser, in cutting thick plates and highly reflective materials has also been the first choice, it is well worth the attention of major manufacturers.

2.YAG laser cutting machine

Advantages:

Able to cut highly reflective materials, such as aluminum, copper and many other non-ferrous materials that can not be cut by laser cutting machines. The manufacturers have mastered the key technology of YAG laser cutting machine, the cost of procurement is low, easy to operate and simple maintenance.

Disadvantages:

Can only cut thin plate materials below 8 mm, slow cutting speed, relatively low efficiency.

Market positioning:

For small and medium-sized enterprises do not require high requirements for the cutting of materials below 8 mm, can be used in sheet metal manufacturing, advertising industry, electronics industry, hardware industry, kitchenware industry, etc.. The current market YAG laser cutting machine has slowly replaced the traditional wire cutting machine, water cutting, CNC cutting, flame cutting and other processing modes.

3. CO2 laser cutting machine

Advantages:

High power, able to cut 25 mm stainless steel, carbon steel and other materials. Non-metallic materials such as acrylic, wood materials, PVC and other materials can be cut up to 60 mm thick. Can cut 4 mm of highly reflective material aluminum plate. CO2 laser cutting machine uses a continuous laser, the cutting surface is smooth when cutting, good cutting quality.

Disadvantages:

The high cost of construction, high-power CO2 laser cutting machine are reached more than 2 million, and the cost of maintenance is very high, the use of the process of photoelectric conversion rate ground, only 10%, high energy consumption. Maintenance is not convenient, the operation requirements are high.

Market positioning:

Mainly positioned in the thick plate cutting, generally 6 to 25 mm high-power laser cutting machine. Today is a continuous technological breakthrough, especially the development of fiber laser cutting machine technology to CO2 laser cutting machine has caused a relatively large impact on the market compression is more powerful, of course, the current market for high-power laser cutting machine is still dominated by CO2 laser cutting machine.

With the application of laser technology is becoming more and more mature, the application of laser cutting machine is becoming more and more widespread, compared to the traditional cutting mode, laser cutting machine cutting surface quality is better, faster, relatively low cost, laser cutting machine will be the mainstream of the future cutting market trends. Currently occupying the largest market share is the fiber laser cutting machine, and the market share has been expanding. Especially in the large-scale metal processing industry fiber laser cutting machine photoelectric conversion efficiency advantages can save a lot of money for the production.

What are the different applications of laser cutting machines for metal processing?

Laser cutting machines are used for a wide range of metal processing applications, including

Automotive industry: Laser cutting machines are used to produce a variety of parts for automobiles, such as body panels, frames and engine components.

Aerospace industry: Laser cutting machines are used to produce aircraft components such as wings, fuselages and engine parts.

Medical industry: Laser cutting machines are used for the production of medical devices and implants, such as surgical instruments and orthopedic implants.

Construction industry: Laser cutting machines are used to produce metal parts for buildings, such as structural beams and cladding.

Jewelry industry: Laser cutting machines are used to create intricate designs and shapes in metal jewelry.

Sign industry: Laser cutting machines are used to produce custom metal signs and logos.

In short, laser cutting machines have revolutionized metal processing, providing high precision, versatility and speed in cutting a wide variety of metals. From the automotive to aerospace, medical and jewelry industries, laser cutting machines have become a must-have tool for many metalworking applications. As technology continues to advance, we can expect laser cutting machines to continue to play an important role in metal processing for years to come.