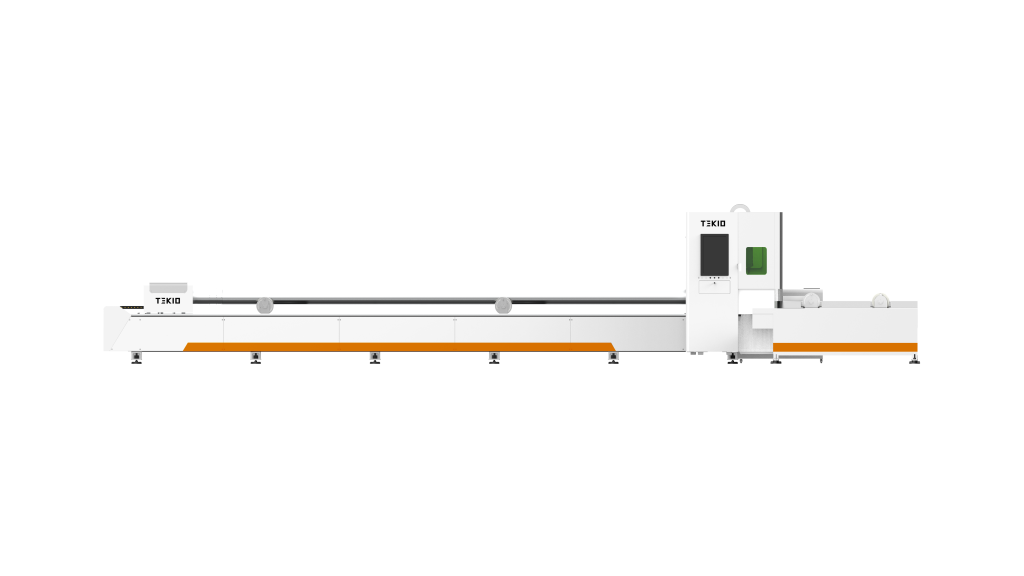

Fiber Laser Tube Cutting Machine T240

Equipped with a special cuting operating system, easy to operate, high precision, professionalism, suitable forspecial profile cutting, while optional follow-on pallet system to reduce cuting costs, widely used in sports equip-ment, petroleum pipelines, chemical equipment and other industries. it can cut carbon steel and stainless steel.

Parameter&configration List

| Item | Subitem | Tekio T240 | Tekio T360 |

| Basic parameter | tube cross-sectional shape | Round pipe, square pipe, rectangular pipe, oval pipe, long round pipe (runway round),and other pipes (Please ask product manager for other cross-section shapes) | Round pipe, square pipe, rectangular pipe, oval pipe, long round pipe (runway round),and other pipes (Please ask product manager for other cross-section shapes) |

| tube size range | Round tube Φ20-Φ240mm Square tube □20 - □240mm Rectangular tube:≤240mm Circumscribed circle diameter≤240mm | Round tube Φ20-Φ360mm Square tube □20 - □360mm Rectangular tube:≤3600mm Circumscribed circle diameter≤360mm | |

| Maximum machinable tube length | 6500mm/9200mm | 6500mm/9200mm | |

| Maximum tube weight | 200Kg 30Kg/m | 500Kg 83Kg/m | |

| Maximum blanking length | standard 2 meters | standard 2 meters | |

| Machine weight | 4500Kg/5800Kg | 4500Kg/5800Kg | |

| Dimensions | 11800×1800×2650mm/14800×1800×2650mm | 11800×1800×2650mm/14800×1800×2650mm | |

| Max. Chuck rotating speed | 130r/min | 80r/min | |

| X axis maximum speed | 150m/min | 150m/min | |

| Y axis maximum speed | 120m/min | 120m/min | |

| X maximum acceleration | 1.5G | 1.5G | |

| Y maximum acceleration | 1.5G | 1.5G | |

| Z axis maximum speed | ≥60m/min | ≥60m/min | |

| Processing precision(□38mm stainless steel square tube) | Φ20mm roundness | ≤0.10mm | ≤0.10mm |

| □20mm square diagonal size difference | ≤0.10mm | ≤0.10mm | |

| □20mm square position size difference | ≤0.15mm | ≤0.15mm | |

| Optical system | Laser source | Ultron laser source | Ultron laser source |

| laser head | TEKIO Laser Head | TEKIO Laser Head | |

| Automatic focusing function of laser head | ● | ● | |

| Multi-stage perforation Technology | ● | ● | |

| smooth cutting technology | ● | ● | |

| mechanical system | Chuck | Fully automatic self centering four jaw chuck- Pneumatic | Fully automatic self centering four jaw chuck- Pneumatic |

| Machine Body | Welded by 8mm Steel Sheet/ Electric CNC Annealing/One-time Milling High Strength Rail Base with thick bearing wall of Rack&Rail | Welded by 8mm Steel Sheet/ Electric CNC Annealing/One-time Milling High Strength Rail Base with thick bearing wall of Rack&Rail | |

| Chuck Qty | 2 chunks (3 chunks optional) | 2 chunks (3 chunks optional) | |

| X-axis、Y-axis、Z-axis、A-axis Servo motor and driver | VEICHI (Front Chucks:3.9Kw Rear Chuck:1.7Kw feed:2.4Kw X-axis:1.1KW Z-axis:400W) | VEICHI (Front Chucks:3.9Kw Rear Chuck:1.7Kw feed:2.4Kw X-axis:1.1KW Z-axis:400W) | |

| Jaw position control | ● | ● | |

| Standard blanking rack | ● | ● | |

| Slideway | PEK | PEK | |

| Rack | T-Win | T-Win | |

| Reducer | EREFAT | EREFAT | |

| Intelligent control system | Control system | cypcut 3000 | cypcut 3000 |

| Cutting Angle Steel and Channel Steel | Optional | Optional | |

| Automatic tube inspection | ● | ● | |

| Display size | 24inches | 24inches | |

| Automatic tube inspection | capacitance, equipment with loading system | capacitance, equipment with loading system | |

| Laser cutting technology database | ● | ● | |

| Auxiliary gas low and high pressure alarm function | ● | ● | |

| Cutting gas automatic pressure regulation function | O2 | O2 | |

| Breaker | France Schneider | France Schneider | |

| Relay | France Schneider | France Schneider | |

| Electrical proportional valve | ●AVENTICS ED05(≤6KW) | ●AVENTICS ED05(≤6KW) | |

| Oxygen Control Valve | AVENTICS | AVENTICS | |

| System identification file format | IGS | IGS | |

| Safety | Rear chuck and roller anti-collision | ● | ● |

| Laser abnormal alarm | ● | ● | |

| Cutting abnormal alarm | ● | ● | |

| Water cooler abnormal alarm | ● | ● | |

| Intelligent Flow Lamp Warning Function | ● | ● | |

| Peripheral system | Water cooler | HanLi/S&A | HanLi/S&A |

| Dust removal | Optional Centrifugal fan | Optional Centrifugal fan |