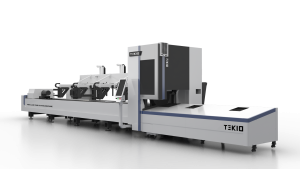

What is the laser cutting process?

Laser cutting is a manufacturing process that uses a high-powered laser beam to cut, engrave or mark a variety of materials, including metals, plastics, wood and glass. The laser beam is highly focused and directed at the material, which is then melted, vaporized or burned away, leaving a clean and precise cut.

The laser cutting process begins with a design file that is uploaded into a computer-aided design (CAD) program. This program then generates instructions that control the movement of the laser cutter and the intensity of the laser. The material to be cut is then placed on the cutting bed and the laser beam is guided onto the material to cut the desired shape according to the programmed instructions. The laser beam is generated by a high power laser and directed onto the material through a series of mirrors and lenses.

There are several types of lasers used in laser cutting, including carbon dioxide lasers, and fiber lasers. Each type of laser has its own unique properties for different materials and thicknesses.

When a laser beam cuts material, it produces a narrow and precise kerf, or cut line, that can be as small as a few thousandths of an inch. The laser beam can also be used to engrave or mark the surface of the material, creating intricate designs, patterns or text.

One of the advantages of laser cutting is that it produces clean, accurate cuts with minimal material waste. It is also an efficient process for cutting intricate shapes and patterns in a variety of materials. In addition, laser cutting can be automated, making it a cost effective and reliable manufacturing process.