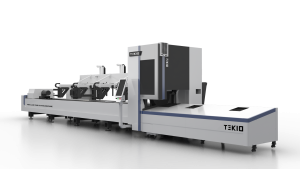

Why fiber laser cutting machine can replace carbon dioxide laser cutting machine

Today, laser equipment is changing rapidly, and as the metal processing market continues to develop, the pace of new equipment replacing old equipment as the new mainstream of the manufacturing industry is accelerating, such as fiber laser cutting machine instead of CO2 laser cutting machine. Why fiber laser cutting machine can replace the CO2 laser cutting machine, we analyze the following from several aspects.

Lower maintenance costs

Fiber laser cutting machines have fewer components than CO2 laser cutting machines, which means they require less maintenance. In addition, fiber lasers do not require a gas laser resonator, which is a component of CO2 laser cutting machines that requires regular maintenance. And fiber lasers are capable of handling harsh operating environments, with a high tolerance for dust, shock, vibration, humidity, and temperature.

Lower operating costs

Fiber laser cutting machine is more energy efficient than CO2 laser cutting machine. CO2 laser cutting machine photoelectric conversion rate is only 8%-10%, while fiber laser cutting machine photoelectric conversion rate can reach 30%. With a 976nm laser pump source, the photovoltaic conversion rate can reach over 40%, and even a 1% improvement in factory production can result in significant long-term cost savings. This means they require less power to operate, which reduces operating costs.

Better beam quality

CO2 lasers produce a beam with greater divergence, which is not suitable for large format processing. Fiber lasers produce a higher quality beam than CO2 lasers, resulting in cleaner cuts and smoother surfaces.

More versatile

Fiber laser cutting machines can cut a wider range of materials than CO2 laser cutting machines, including metals, plastics, and composites. Additionally, fiber lasers can be used for welding, marking, and engraving, which makes them a more versatile tool for manufacturers.

Overall, fiber laser cutting machines offer several advantages over CO2 laser cutting machines, including higher cutting speed, lower maintenance and operating costs, better beam quality, and more versatility. As a result, they are quickly becoming the preferred choice for manufacturers who need precise and efficient cutting solutions